DISTILLERY

Indiana Sucrotech (Pune) Pvt Ltd. has contributed a lot in sugar industry by providing various turnkey solution plants since last 35 years.

Indiana Suctrotech has entered into design, manufacture & supply of turnkey solution plants for Fuel Ethanol & Extra neutral alcohol (ENA) of various capacities based on customer requirements.

MOLASSES BASED ETHANOL

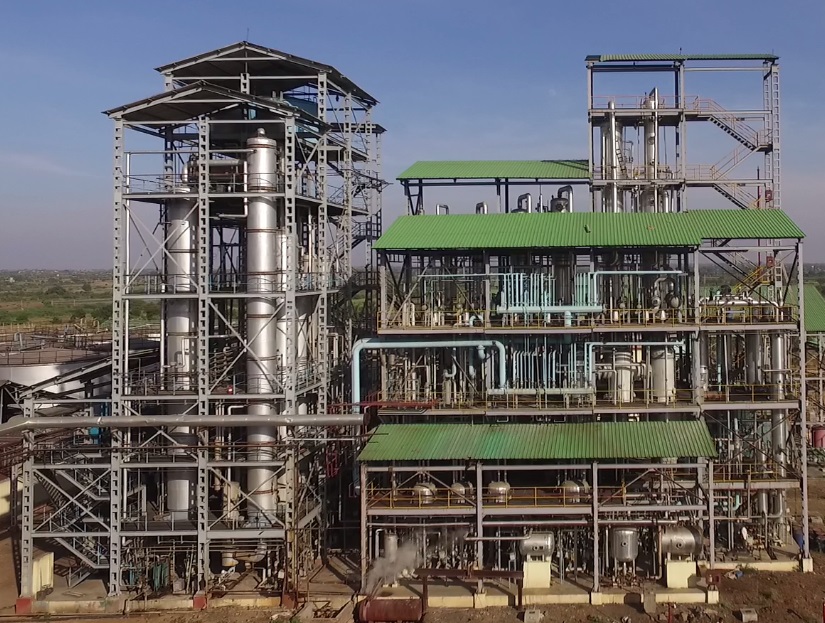

DISTILLERY PLANT

This plant has various sections consists of Fermentation, Distillation, Dehydration Evaporation, Decantation, Water treatment, Firefighting, Utility, Raw material storage, Product Storage section.

GRAIN BASED ETHANOL DISTILLERY PLANT

Selection of the appropriate feedstock depends on a number of factors, not the least of which is the geographical / climatic environment of the intended production site.

In dry milling, the entire grain kernel is first ground into “meal,” then slurried with water to form a “mash.” Enzymes are added to the mash to convert starch to sugar. The mash is cooked, then cooled and transferred to fermenters. Yeast is added and the conversion of sugar to alcohol begins.

This plant has various sections consists of Milling, Fermentation, Distillation, Evaporation, Dehydration, Decantation, Drying, Water treatment, Firefighting, Utility, Raw material silos, Product Storage section.

SUGARCANE JUICE TO ETHANOL PLANT

BEET JUICE TO ETHANOL PLANTS

Generally, One acre of sugar beets will produce about 1930 kg ethanol. Sugar beet is a more versatile crop than sugar cane since it can tolerate a wider range of soil and climatic conditions. Once processed in a sugar plant, beet molasses are generated in large volumes from the sucrose recovery operation and can be fed to the ethanol production unit.

- Washing

- Mashing / Clarification / Extraction

- Evaporation

- Fermentation with standard yeast (batch or continuous)

- Distillation

- Rectification (if applicable)

- Ethanol dehydration (molecular sieve)

- Vinasses treatment

EXTRA NEUTRAL ALCOHOL (ENA)

The highest level of ethanol purity is “ENA” or Extra Neutral Alcohol for High quality beverages and liquor. Extra Neutral alcohol (ENA) is the finely distilled and made from different (raw) materials such as sugarcane molasses or grains (Grain Neutral Spirit) examples of grains include corn, rye, wheat, barley, and rice. It is organoleptically neutral – it has no taste or smell. It is the purest form & not contains any impurities. It is used in mixed drinks, in the production of liqueurs, for medicinal purposes, and as a household solvent.